What is preventive maintenance pdf

Preventive maintenance is defined as regularly scheduled inspections, tests, servicing, replacements, repairs and other tasks intended to help reduce the impact and frequency of equipment failures. This includes scheduled preventive maintenance, predictive maintenance and inspection activities. The

Corrective maintenance is a maintenance task or operation done in order to identify, isolate or separate and rectify a particular fault. This is performed in order to restore the failed machine, equipment or system to an operational condition.

Preventive maintenance refers to maintenance action performed to keep or retain a machine/equipment or asset in a satisfactory operating condition through periodic inspections, lubrication, calibration, replacements and overhauls.

Preventive Maintenance ⠀漀爀 倀䴀尩 is the art of preservation clad in a cyclical process of inspections. PM is the diagnostic to൯l of facilities management as well as the preservative for the physical plant. It prevents potential problems from occurring. 對 PM is comprised of planned maintenance procedures intended to ensure that the school operates at its proper efficiency

Preventive maintenance ( 1951 ): It is a daily maintenance ( cleaning, inspection, oiling and re-tightening ), design to retain the healthy condition of equipment and prevent failure through the prevention of …

Once the status of the facility is known, there is a clearer understanding of the impending maintenance and repair needs, and an opportunity to plan and schedule out capital renewal projects, preventive maintenance and repair needs, and create a schedule to attack any backlog of deferred maintenance …

Predictive maintenance is the complement of preventive maintenance. Through the utilization of various Through the utilization of various nondestructive testing and measuring techniques, predictive maintenance determines equipment status

Preventive maintenance also helps you avoid the high cost of emergency repairs, enables you to keep your equipment operating at optimal efficiency and pays you back with as much serviceable life from your equipment as possible.

Types of Maintenance Programs that exceptional maintenance practices encompassing preventive and predictive elements can extend this period. The wear-out period is characterized by a rapid increasing failure rate with time.

FROM REACTIVE MAINTENANCE TO PROACTIVE PREVENTIVE

Types of Software Maintenance Computer Notes

Preventive maintenance (or preventative maintenance) is basically a type of maintenance that is done at a regular interval while the equipment is still functioning with the objective of preventing failure or reducing the likelihood of failure.

Preventive Maintenance In order to maintain the highest level of productivity and quality, preventive maintenance of presses and tooling is required. The following tips are presented as aids to help you achieve that goal. Presses The preventive maintenance required for any molding press is found in the press manufacturer‘s maintenance manual. Molds Ejector and Guide Pin Lubrication When a

Fundamentals of Preventive Maintenance JOHN M.GROSS American Management Association New York • Atlanta • Brussels • Buenos Aires • Chicago • London • Mexico City

Preventive Maintenance Keep records of all your maintenance activities, indicating the machine(s) involved, the part(s) involved, type of maintenance and date on which performed. training Maintenance personnel are often involved in a complex and changing set of problems. Therefore, they need more thorough training in accident prevention than regular workers. Serious consequences to maintenance

Preventive maintenance is the foundation of the entire maintenance strategy. Unless the PM program is effective, all subsequent maintenance strategies take longer to implement, incur higher costs and have a higher probability of failure.

Designed for 5+ employees — Superior Preventive Maintenance & Business Management Software for your security, fire, solar, electrical, plumbing or HVAC business — Easily manage maintenance & repair work — Monitor & manage preventative maintenance work to provide superior service & …

Preventive Maintenance Strategy By Terry Harris, CMRP As I roam the US and the world in teaching people and companies, how to make their equipment last longer. I find that every plant I encounter has some form of preventive maintenance program. I am often confused by the process that is used to develop the program […]

Preventive maintenance, or PM, is regular, planned maintenance that is scheduled according to usage or time-based triggers. The purpose of PM is to lessen the likelihood of equipment breakdowns. There are many instances in which preventive is the best maintenance strategy to use, and it’s much easier to carry out a PM strategy with the help of maintenance software.

1 Introduction on Planned Maintenance 1.1 Understanding the Need For A Planned Maintenance System 1.2 Planned Maintenance Defined 1.3 What Planned Maintenance System Includes 1.4 Equipment’s 6 Big Losses 1.5 World Class Maintenance Management System 1.6 Different Approaches on Planned Maintenance 1.7 What Planned Maintenance Wants to Achieve 2 Phase 0 : …

The term preventive maintenance (also known as preventative maintenance) implies the systematic inspection and detection of potential failures before they occur. PM is a broad term and involves varying approaches to problem avoidance and prevention depending upon the criticality of the data center. Condition-based maintenance, for example, is a type of PM that estimates and projects equipment

A preventive maintenance schedule is a scheduled maintenance or service check of an equipment. Preventive maintenance periodically checks an equipment to ensure that the equipment is operating properly and to avoid unscheduled breakdown of the machine, …

Preventive maintenance is an important part of facilities management. The goal of a successful preventive maintenance program is to establish consistent practices designed to improve the performance and safety of the equipment at your property.

Learn 6 preventive maintenance procedures to keep your PLC system running fault free Learn a step-by-step procedure for finding hidden ground loops Learn how to deal with leaky inputs Identify vibration problems and use them for preventive engineering control Control excessive line voltage and avoid intermittent shutdowns PROGRAMMING Learn the number systems and codes used in PLC …

Preventive maintenance is a schedule of planned maintenance actions aimed at the prevention of breakdowns and failures. The primary goal of preventive maintenance is to prevent the failure of

Preventive maintenance is the concept wherein, operators produced goods using machines and the maintenance group was dedicated with work of maintaining those machines, however with the automation of Nippondenso, maintenance became a problem, as more maintenance …

ScheduledMaintenance(! Scheduled(Maintenance(! Scheduled!maintenance!is!planned!componentrepair!or!replacement,!often!triggered! by!preventive!maintenance!inspections

Preventive maintenance helps to prevent failure of parts, materials, and systems by ensuring that they are in good working order. Troubleshooting is a systematic approach to …

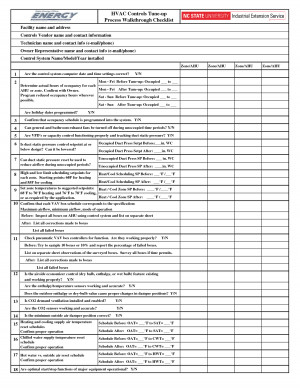

Despite my relatively short amount of time working in the building commissioning field, I have been able to witness firsthand the serious consequences resulting from a lack of HVAC preventive maintenance …

What is Preventive Maintenance IGI Global

Regular preventive maintenance helps facilitate forward budget planning. The main point of concern in ageing and the life expectancy of transformers is the condition of the insulation system, which is typically based on organic products.

Project overview Build preventive maintenance scheduler Assess potential losses Find frequency of failure Determine optimal maintenance policy

Preventative maintenance is any maintenance that is designed to maintain the best working condition of equipment, thereby preventing any failure. In a preventative maintenance program, vehicles are brought in for inspection and maintenance on a strict schedule, even if it’s only for an oil change.

Having a preventive maintenance checklist and procedures make staying on top of regular maintenance easy, no matter what limitations you might have in terms of staff, time, and budget. Creating a preventive maintenance program will save money by including these planned repairs into your budget and schedule, avoiding the high costs of an emergency repair. – soil erosion prevention methods pdf Preventive, Predictive and Corrective Maintenance Presented by: John D. Szwedo. Baxter & Woodman, Inc. Consulting Engineers. www.baxterwoodman.com

Plant Maintenance Overview PM_200 PM Overview – PM_200 (v2) 2 • Unit 1 – The Plant Maintenance Process • Unit 2 – Notifications (Work Requests) • Unit 3 – Work Orders • Unit 4 – Materials • Unit 5 – Time Processing • Unit 6 – Equipment • Unit 7 – Reports Course Content. PM Overview – PM_200 (v2) 2 PM Overview – PM_200 (v2) 3 • Prerequisites PM UK_100 IRIS/SAP

Preventive maintenance (PM) is a time-based or interval-based planned service to detect and prevent potential failures and extend the life of equipment. It is planned maintenance of a plant and its equipment that is designed to improve equipment life and avoid any unplanned maintenance activity. PM includes painting, lubrication, cleaning, adjusting, and minor component replacement to extend

Preventative maintenance can extend the life of a home’s systems, equipment and materials. Some examples of systems that benefit from preventative maintenance include ventilation systems, water fixtures, and automatic sensors.

Preventive maintenance, on the other hand, is a carefully designed maintenance program (often using CMMS software) where maintenance tasks are performed routinely in order to …

Predictive vs. Preventive Maintenance. Though both methodologies work to extend the life of assets, prevent unexpected breakdowns and save organizations money, Preventive Maintenance (PM) and Predictive Maintenance (PdM) are very different approaches.

preventive maintenance. The establishment of this task force subsequently led to the development of a The establishment of this task force subsequently led to the development of a series of guidelines for airlines and aircraft manufacturers to use, when establishing maintenance

The Role of CMMS 1 Computerized Maintenance Management Systems (CMMS) have evolved over the last three decades from elementary asset tracking and preventive maintenance functionality, to enterprise maintenance

POLICY DOCUMENT Maintenance Management Framework Policy for the maintenance of Queensland Government buildings Department of Housing and Public Works

During a preventive maintenance on an installation, a maintenance report is made up, in which all hydraulic, pneumatic, electrical and mechanical parts are checked. Remarks are noted in the maintenance report of which the customer receives a copy.

preventive maintenance to be carried out, improve and ensure maximum utilization of maintenance facilities, and improve the maintenance organization. For understanding the most used maintenance systems (fig. 1) is necessary to define some terms[2],[3]: Fig. 1 Maintenance systems

Preventive, and even predictive maintenance, is when an organization conducts maintenance activities, including inspections, to help ensure equipment is functioning within their expected parameters and to catch indications of minor issues, so that they can be addressed before a bigger problem occurs.

preventive maintenance system includes moving the site from breakdown maintenance to preventative maintenance, ensuring that all statutory compliance obligations are met, eliminating frequent causes of loss of reliability and reducing the cost of maintenance.

Maintenance & Repair Module 1 Table of Contents Chapter Topic Page 1. Maintenance Management 1 1.1 Types of Maintenance Strategies 1 1.2 Shift from Unscheduled Work to Scheduled Work 2

There are four types of maintenance, namely, corrective, adaptive, perfective, and preventive. Corrective maintenance is concerned with fixing errors that are observed when the software is in use.

Hartford Steam Boiler Standard for an Electrical Preventive Maintenance (EPM) Program Page 2/10 and/or connectors are used together, examine connections for signs of

What Is The Difference Between Preventative Breakdown

Although preventive and corrective maintenance should be part of any maintenance contract (and it is highly recommended at fixed cost per year), adaptive and perfective maintenance could be covered by separate ad-hoc contracts and/or on a time/material basis.

Preventive maintenance is a procedure designed to prevent failures and prolong the life of infrastructure, facilities, machines, software and other entities such as documents.

What is Preventive Maintenance? Definition of Preventive Maintenance: The systematic control, detection, correction and prevention of faults that are still in …

The Difference Between Predictive Maintenance and Preventive Maintenance Imagine you purchased a new economy car three months ago. To get around, you alternate between riding a bike, walking, and driving your new car.

Preventive Maintenance Preventive maintenance means taking precautions over a machine before anything happens to it. It is done on a machine when it is shut down for all maintenance reasons. It is done with the total period of functionality of the machine in view.

Preventive and Predictive Maintenance Concepts

Difference Between Preventive and Predictive Maintenance

Preventative Maintenance …the art of maintaining equipment to achieve the optimal service life, efficiency and performance, and to prevent breakdowns. What is required simply, is to get all mechanical components internally clean (externally helps also), keep them clean, and feed them with clean oil, clean fuel and clean air as necessary.

A single interface for all maintenance: Pick a program that can handle both unplanned (breakdown) as well as planned preventive maintenance. This makes it easier to track and manage all the maintenance done on an equipment.

A/C Preventive Maintenance Checklist Checklist for proper preventive maintain of your AC system. Home / Residential Air Conditioning / A/C Preventive Maintenance Checklist. Air Conditioning Preventive Maintenance Checklist. You wouldn’t drive your car 100,000 miles without changing the oil. The same logic holds true for your home comfort system. Regular A/C preventive maintenance is …

Asset Management (Maximo) Using the Internet of Things for preventive maintenance. Highlights – Gain operational effectiveness and ROI with the Internet of Things (IoT) and business analytics. – Infuse your asset management system with new cognitive capabilities for immediate insight into asset health and optimal preventive maintenance scheduling. – Manage your full asset portfolio with

Preventive Maintenance Principles SPL 7.2 Scott Couzens, LFM ’06 Scott Hiroshige, LFM ‘06 Presentation for: Summer 2004 i Erik Smith, LFM ’03 – Intel Corporation

Preventative maintenance is work done on a repeating schedule to prevent failures or breakdowns. This could include monthly inspections, parts replacements, or detection reporting. The goal of preventative maintenance is to detect and avoid issues before they become an issue.

How are Preventive & Predictive Maintenance Different

What is Preventive Maintenance? Definition from

18/12/2018 · Preventive or preventative maintenance is routine maintenance which is designed to prevent the need for more costly repairs. By regularly engaging in activities which contribute to the upkeep of a home, a homeowner may be able to sidestep serious problems which arise as a result of neglect, and more expensive maintenance can be delayed.

Preventive maintenance or preventative maintenance (PM) has the following meanings: The care and servicing by personnel for the purpose of maintaining equipment in satisfactory operating condition by providing for systematic inspection, detection , and correction of incipient failures either before they occur or before they develop into major defects.

The act of a regularly scheduled check of the computer hardware or software to help ensure it continues to operate properly. Below is a list of some preventive maintenance steps you can take with your computer or computer hardware.

Maintenance done as explained in this book is not a cost. Great maintenance is a ‗rainmaker‘ of Great maintenance is a ‗rainmaker‘ of moneys now lost to waste, catastrophe and misunderstanding.

Maintenance & Repair Module 1 – Startseite

Planned Preventive Maintenance What Does It Really Mean?

Best Preventive Maintenance Software 2018 Reviews of the

fire protection and prevention act 1997 pdf – Preventive maintenance definition of preventive

Preventive Maintenance Strategy for Data Centers APC

A Preventive Maintenance Checklist grainger.com

What to Include on Your Facilities Preventive Maintenance