Atlas copco air compressor preventive maintenance checklist pdf

For all of your air compressor needs Air Center, Inc. will be able to help. Air Center stocks many air compressor parts and filters for major manufacturers, designs and installs compressed air systems, and employs technicians who are able to service any compressed air equipment.

Maintenance on Rotary Screw Air Compressor – การดูแลปั๊มลม Rotary Screw พื้นฐาน – การดูแลปั๊มลม rotary screw

Oil-injected Rotary Screw Compressors The WorkPlace Air System . First in Mind—First in Choice™ Atlas Copco: Customized Quality Air Solutions through Innovation, Interaction and Commitment. Total capability, total responsibility At the heart of your operation, Atlas Copco delivers quality compressed air for superior operational capacity. Choose from our range of products to build a

Guardian is a complete Compressed Air Maintenance Solution for your new installation, providing a comprehensive 7-year service plan. When protected by Guardian, your Compressed Air Equipment regularly receives preventive maintenance performed by …

Preventative maintenance and top performance with genuine spare parts from the company that knows your Atlas Copco gas and process turbomachinery inside and out . Around the globe Superior customer service in more 180 markets around the world.

of the right quality of air. The Atlas Copco Z compressor series is focused on effectively saving energy, ensuring product safety – only oil-free machines exclude contamination risks Energy, safety & reliability for 100% – and guaranteeing the utmost reliability around the clock. And not just today, but day after day, year after year, with minimal maintenance cost, few service

Atlas Copco is a world-leading provider of sustainable productivity solutions. We serve customers in more than 180 countries with products and service focused on …

Having this routine maintenance performed by professional factory-trained specialists will optimize your compressor up-time, improve the quality of the air delivered, extend the life of your equipment, and reduce the amount of power your compressed air system consumes (lower your power bill.)

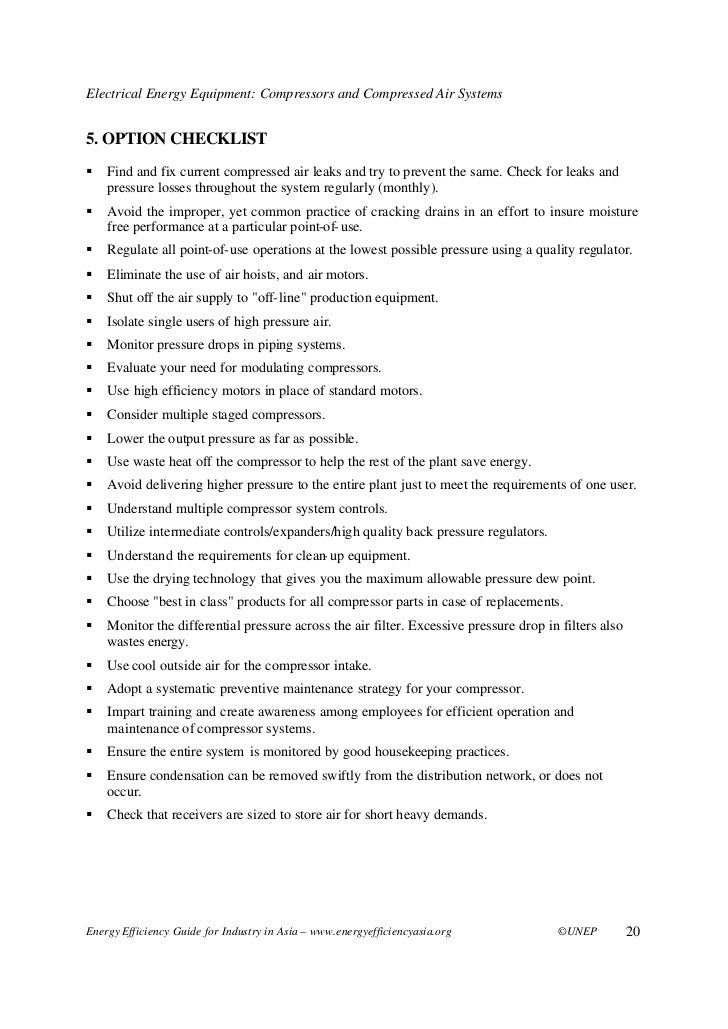

Preventive Maintenance Strategies for Compressed Air Systems;Industrial Technologies Program (ITP) Compressed Air Tip Sheet #6 (Fact Sheet) Subject BestPractices Program tip sheet discussing how to eliminate inappropriate uses of compressed air.

Is there any additional maintenance needed? If Yes, is it urgent? START TIME: END TIME: . RECIPROCATING COMPRESSOR MAINTENANCE CHECKLIST DATE OF INSPECION: MODEL NUMBER: (HP): CUSTOMER NAME: SERIAL NUMBER:

Used Atlas Copco GA18VSDFF API432-747 . Part number: GA18 VSD 460FF API432747 . COMPRESSOR FEATURES OVERVIEW Horse Power: 25 HP . FAD: 34-127 CFM

Following a properly scheduled compressed air system maintenance checklist is crucial to maintain not only performance and efficiency but also to maximize the life expectancy of your compressed air …

The first choice in Missouri, Illinois, and Kansas for servicing Sullair, Kaeser, Quincy, and Atlas Copco air compressors and dryers is HTE Compressed Air Solutions. For information on our Preventative Maintenance Programs, click on the “Planned Maintenance” icon shown above.

A compressed air machine that needs a particular air quality output for medical, electrical, or food processing purposes uses a compressor filter of a specific type – particulate, carbon, or coalescing – and these filters should be carefully checked and changed or …

Compressor Preventative Maintenance Contract feldfire.com

Compressor Preventative Maintenance

compressed air with a pressure dewpoint as low as -40°C/-40°F, Atlas Copco desiccant dryers eliminate system failures, production downtime and costly repairs. competitive performance A dewpoint down to -40°C/-40°F together with simple and easy controls guarantee the dryer operates in the best way possible. limited maintenance Atlas Copco dryers have a small footprint thanks to the all-in

Get the most out of your equipment with full air compressor service and maintenance Australia wide by Altas Copco. Give us a call on 1800 023 469 today. – Atlas Copco …

Best practices in providing a checklist for the grants of 1No Atlas Copco Air Compressor, of workers to noise should not exceed 90 decibels dBA daily; PHYSICAL RESEARCH LABORATORY (A …

JHF System Maintenance Air Compressor Maintenance Checklist . Owning an air compressor is a big responsibility. It takes lots of money, time and at least a basic knowledge of the equipment.

Air CoMPreSSorS MAinTenAnCe & TroubleShooTing Daily Topics day One Overview of air compressors technical features • Overview of air compressors technical features • Classification of air compressors based on design and application • World standards and codes related to air compressors • Main features of centrifugal & axial compressors • Comparison between positive displacement

ATLAS COPCO – PORTABLE AIR DIVISION www.atlascopco.com Printed matter N° 2954 3190 01 05/2008 Instruction Manual for Portable Compressors XAMS 407 Cd – XAMS 850 CD7

ATLAS COPCO – PORTABLE ENERGY DIVISION www.atlascopco.com Printed matter N° 2954 7540 00 10/2013 Instruction Manual for Portable Compressors XAS 67 – XAS 130

Air Compressor Preventive Maintenance Checks Checking Compressor Pump Oil Level Unless your air compressor is an oil free compressor, do not operate without lubricant or with inadequate lubricant.

Atlas Copco Air Compressor Preventive Maintenance design templates let you using again the same design and styles in several documents. Sad to say, Atlas Copco Air Compressor Preventive Maintenance are usually misunderstood in addition to underused considering that successfully using them takes a bit of specialised knowledge.

Atlas Copco is the world leader in compressed air technology, with over 100 years of experience in air compression systems. The lowesT operaTing cosT The highesT reliabiliTy energy savings with VSD investment maintenance energy . 4 An energy efficient machine saves money only if it runs reliably around the clock. And not just today, but day after day, year after year; with minimal service

Compressor Preventative Maintenance Contract At the request of (hereinafter referred to as “Purchaser”), Ed M. Feld Equipment Co., Inc. agrees to perform a Preventative Maintenance …

3/08/2013 · Attached is a Pneumatic Power System, Air Compressors, Compressed Air Hoses and Hose Attachments. Appendix N (a) Pumper Inspection Check List 1 …

Blue Diamond Machinery also provides comprehensive range of air compressor servicing, preventative maintenance and compressor repair services across Perth, WA. With over 25 years of experience servicing all types of compressors our service team ensure minimum downtime, quality and reliability on all compressor service and repair work.

Rotary Screw Maintenance Schedule ACTION • Monitor all gauges and indicators for normal operation • Check oil level • Drain control line fi lter • Observe for oil leaks • Observe for unusual noise or vibration • Fill out Daily Check List • Check safety valve operation • Drain any air receivers in system • Drain water out of oil • Check to make sure moisture separator is

Atlas Copco is the world leader in compressed air technology, with over 100 years of experience in air compression systems. THe loweST opeRATinG CoST THe HiGHeST ReliAbiliTy energy savings with VSD investment maintenance energy . 4 An energy efficient machine saves money only if it runs reliably around the clock. And not just today, but day after day, year after year; with minimal service

Atlas Copco High-pressure oil-free air piston compressors P 37 – P 160 / 25 to 40 bar / 37 to 160 kW . By combining the right mix of innovation, high-tech components and a simplified, user-oriented design, Atlas Copco’s P compressor range is ready to be your partner for excellence. P compressors give the highest possible quality and reliability for your process, while offering the lowest

Preventative Maintenance for Industrial Air Compressor Systems . Details Category: Blog Published on Monday, 22 July 2013 07:40 Written by Super User Hits: 6054 All businesses that utilize air compressors know that a well-maintained air compressor is an air compressor working at maximum efficiency. Proper maintenance can prevent problems and save energy and repair costs. Most air …

Atlas Copco can help you map the load/air demand profile of your current compressor and blower installation and indicate potential energy savings with VSD compressors and blowers. For more information, please contact your local Atlas Copco representative.

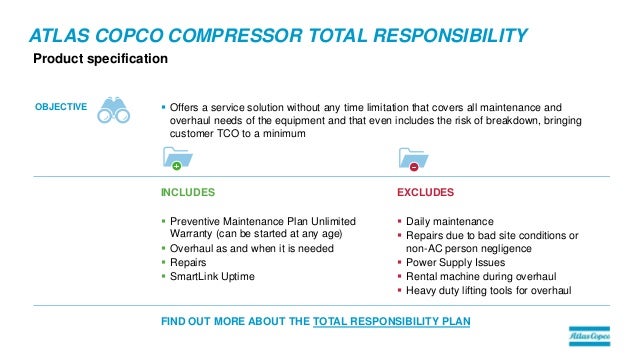

ATLAS COPCO COMPRESSOR MAINTENANCE PLAN Product specification OBJECTIVE Offers a service solution where the preventive maintenance of the equipment is planned and carried out according to its instruction manual and local conditions INCLUDES Genuine parts and lubricants / delivery All labour & travel (optional inspection) Maintenance schedule Comprehensive diagnostics / …

Portable Air Compressor Maintenance Checklist Every

Download as PDF, TXT or read online from Scribd. Flag for inappropriate content . Download. Save . Maintenance Compressor – Presentasi. For Later. save. Related. Info. Embed. Share. Print. Search. Download. Jump to Page . You are on page 1 of 14. Search inside document . 6/7/2011. Compressor Atlas Copco M. Yazid 7 Juni 2011 Compressor Jenis‐jenis Compressor : ‐ Hermetically sealed

Cost Savings with Air System Maintenance System Pressure: 100 psig Maintenance Complete. P reventive maintenance is the solution to keeping your compressed air system in top condition. While the life cycle of any industrial air compressor typically exceeds ten years, proper maintenance is crucial to maintain performance and efficiency. Compressors can be divided into seven sub …

Atlas Copco Maintenance Manual All fluids are plumbed to the edge of the skid for easy access and quick maintenance. Dependable Ensure reliable starts and predictable power generation. – substance abuse relapse prevention plan pdf 1 of 2 Maintenance checklist – Compressed Air Carry out the maintenance checks below on your compressor and compressed air system. For more information on Compressed Air systems download CTV017 – Compressed air technology overview

17/10/2016 · Atlas Copco Compressor Technique Scales Gives Step-By-Step Details Of Proper Preventative Maintenance For Rotary Screw Air Compressor – Duration: 7:02. Quincy Scales Industrial 14,649 views. 7

Preventive Compressor Maintenance – the way to ensure your uptime The best way to ensure that you do not suffer unplanned compressor down-time, is to make sure that your compressed air equipment is serviced and maintained regularly.

compressed air with a pressure dewpoint as low as -40°C/-40°F, Atlas Copco desiccant dryers eliminate system failures, production downtime and costly repairs.

Air Compressor Maintenance Manual vtr 1000 sp2 air compressor manuals- need an owners manual daisy188 tips for air compressor maintenance – air

Sullair offers a range of compressed air services for all makes and models. We provide a range of support services from installation, commissioning, routine and programmed maintenance, 24/7 breakdown service, hands-on and online training.

Increase energy efficiency and optimize your compressor uptime with a preventive maintenance plan. Cookies on the Atlas Copco website Cookies help us deliver our services.

basic preventive maintenance check list for reciprocating (piston) air compressors: Before performing any maintenance function on your rotary screw compressor, switch main disconnect switch to “off” position to assure no power is entering unit.

Atlas Copco instruction book / rev: Atlas Copco logbook: 4.2 Preventive Maintenance Schedule For The Compressor 16 4.3 Lubrication oils 17 4.4 Oil Level Check 17 4.5 Oil And Oil Filter Change (see Fig. 4.5) 18 4.6 Cleaning Coolers 18 4.7 Battery Care 19 4.8 Storage 19 4.9 Service Kits 19 5 Adjustments and Servicing Procedures 20 5.1 Adjustment of the Continuous Regulating System (See …

26/12/2018 · Portable Air Compressor Maintenance Checklist By Edward Allen On November 2, 2015 In Industrial Equipment Portable air compressors are some of the most versatile pieces of compressing equipment you can find on the market.

Page 1 of 2 Atlas Copco Air Compressor Pre-Start Procedure The following checks should be performed prior to starting the air compressor. A visual inspection should only take a few minutes and can prevent damage, accidents .and lost time

Ask your ATLAS air compressor distributor about wire flexed hoses, automatic tank drains, low oil monitors, refrigerated air dryers, and other Atlas air compressor accessories. ATLAS is committed to provide reliable clean dry compressed air at the most competitive price.

Preventive maintenance for turbo machinery Atlas Copco China

A dry compressed air system is essential to maintain the reliability of production processes and the quality of your end products. Untreated air can cause corrosion in pipe work, premature failure of pneumatic equipment, and product spoilage.

4.4.14 start the air compressor and check the amperage of the motor. if found within the limits, stop the air compressor. 4.5 annual preventive maintenance checks: 4.5.1 remove dust dirt by emery paper and paint the compressor and related equipments like condenser, receiver etc,.

Cetia.co.ltd Thailand – Preventive Maintenance on Screw

Air Compressor Maintenance Checklist JHF

Preventative Maintenance for Industrial Air Compressor Systems

Atlas Copco Air Compressor Pre-Start Procedure

Air Compressor Service Plans by Atlas Copco SlideShare

Air Compressor Maintenance Guide portlandcompressor.com

https://fr.wikipedia.org/wiki/Maintenance_pr%C3%A9ventive

The Compressed Air Blog Atlas Copco Compressors’ blog

– Air Compressor Guide Cost Savings with Air System Maintenance

BRE Air Compressors from Atlas Copco • Scotland UK

Maintenance checklist Compressed Air

Atlas Copco Instruction Manual mining.tcgc.ru

Compressor Preventative Maintenance Contract feldfire.com

Air Compressor Service & Maintenance Atlas Copco Australia

Atlas Copco is a world-leading provider of sustainable productivity solutions. We serve customers in more than 180 countries with products and service focused on …

Get the most out of your equipment with full air compressor service and maintenance Australia wide by Altas Copco. Give us a call on 1800 023 469 today. – Atlas Copco …

Preventative Maintenance for Industrial Air Compressor Systems . Details Category: Blog Published on Monday, 22 July 2013 07:40 Written by Super User Hits: 6054 All businesses that utilize air compressors know that a well-maintained air compressor is an air compressor working at maximum efficiency. Proper maintenance can prevent problems and save energy and repair costs. Most air …

Blue Diamond Machinery also provides comprehensive range of air compressor servicing, preventative maintenance and compressor repair services across Perth, WA. With over 25 years of experience servicing all types of compressors our service team ensure minimum downtime, quality and reliability on all compressor service and repair work.

Preventative maintenance and top performance with genuine spare parts from the company that knows your Atlas Copco gas and process turbomachinery inside and out . Around the globe Superior customer service in more 180 markets around the world.

3/08/2013 · Attached is a Pneumatic Power System, Air Compressors, Compressed Air Hoses and Hose Attachments. Appendix N (a) Pumper Inspection Check List 1 …

Atlas Copco can help you map the load/air demand profile of your current compressor and blower installation and indicate potential energy savings with VSD compressors and blowers. For more information, please contact your local Atlas Copco representative.

Best practices in providing a checklist for the grants of 1No Atlas Copco Air Compressor, of workers to noise should not exceed 90 decibels dBA daily; PHYSICAL RESEARCH LABORATORY (A …

Following a properly scheduled compressed air system maintenance checklist is crucial to maintain not only performance and efficiency but also to maximize the life expectancy of your compressed air …

Atlas Copco is the world leader in compressed air technology, with over 100 years of experience in air compression systems. THe loweST opeRATinG CoST THe HiGHeST ReliAbiliTy energy savings with VSD investment maintenance energy . 4 An energy efficient machine saves money only if it runs reliably around the clock. And not just today, but day after day, year after year; with minimal service