Predictive and preventive maintenance pdf

In reality, predictive maintenance is a condition-driven preventive maintenance program. Predictive maintenance is not a substitute for the more traditional maintenance management methods. It is a valuable addition to a comprehensive, total plant maintenance program. Where traditional maintenance management programs rely on routine servicing of all machinery and fast response to unexpected

Making factories smarter, more productive through predictive maintenance 3 October 2016 products designed for industrial applications, along with the expertise and commitment to bring predictive maintenance and other smart factory benefits to manufacturing plants worldwide. Savings from predictive maintenance Scheduled preventive maintenance is based on historic information …

• Utilize predictive analytics to identify when internally used production machinery, equipment, and assets are likely to fail or need service, and perform preventive

•Preventive •Predictive Estes, McClure & Associates, Inc. Engineering and Consulting Preventive Maintenance •Series of actions performed that are designed to detect, preclude, or mitigate degradation of a system or its components •Time-based maintenance Estes, McClure & Associates, Inc. Engineering and Consulting HVAC PM “Where to Start”? •ASHRAE Standard 180 •Manufacturer’s

Electric Motor Predictive and Preventive Maintenance Guide Electric motor failure could result in lost capacity as well as excessive repair and maintenance costs. This guide provides information on establishing an effective maintenance program to help prevent unexpected motor failures, costly downtime, and unnecessary maintenance costs. Specifically, the guide summarizes technical data

“Predictive maintenance” is a term easiest to describe in relation to preventive maintenance methods. With preventive maintenance, work is performed based on a schedule, which is usually created using historical knowledge of how—and how often—a particular asset breaks down. According to a

Predictive maintenance (PdM) is maintenance that directly monitors the performance and condition of equipment during normal operation to reduce the likelihood of failures. Also known as condition-based maintenance, predictive maintenance has been formally utilized in the industrial world since the

8/31/2015 1 Preventive/Predictive Maintenance Systems APPA INSTITUTE FOR FACILITIES MANAGEMENT This is your session Administrivia Who are you?

Preventive and Predictive Maintenance. At DeBra-Kuempel, we know the importance of keeping your heating and cooling systems finely tuned. A reliable, efficient HVAC system ensures that your processes and staff are working efficiently, too.

Summary Predictive maintenance is surely one of the most talked-about topics in maintenance and asset management. In order to find out where companies currently stand regarding predictive maintenance,

Preventive maintenance (1951): It is a daily maintenance (cleaning, inspection, oiling and re-tightening), design to retain the healthy condition of equipment and prevent failure through the prevention of deterioration, periodic inspection or equipment condition diagnosis, to measure deterioration. It is further divided into periodic maintenance and predictive maintenance. Just like human life

For the purpose of this guide to Preventive Maintenance (PM) and Predictive Maintenance (PDM), I will use the following definition: PM and PDM are a series of tasks and company policies that, if followed, improve and keep business profits as high as possible. This is achieved by adhering to three general guidelines.

maintenance, but is less efficient and effective than the optimal approach, predictive maintenance. Like preventive maintenance, predictive maintenance is based on the tenet that a proactive approach is better than a reactive one. However, instead of making repairs based on a predetermined calendar schedule, the predictive approach makes repairs based on the actual condition of the equipment

PDF Increasing yield, eliminating unexpected downtime, and reducing maintenance costs are some of the potential benefits that a predictive monitoring system can provide for semiconductor

Vibration measurements in predictive maintenance by Christian Claessens, Mobil Plastics Europe Inc. Introduction In July 1980, the first production partment with its workshops, labora- last two and a half years, the alterna-

In general (most of the time but not always) Reliability Centred Maintenance prefers the use of Predictive Maintenance tasks to Preventive Maintenance tasks when determining an optimum Predictive and Preventive maintenance program. This is because (again, in general, and where technically feasible), Predictive Maintenance tasks maximise equipment uptime and component life …

Products Preventive Maintenance PMP and LEAP Breakers

Preventive and Predictive Maintenance Central Mechanical

predictive maintenance delivers the most significant benefits: the production line, field level customer service and warranty claims. Preventive maintenance in action Motorcycle manufacturer By adding predictive maintenance capabilities to its warranty claims, a leading motorcycle manufacturer reduced the time to detect quality issues from days and weeks to minutes and hours, thereby

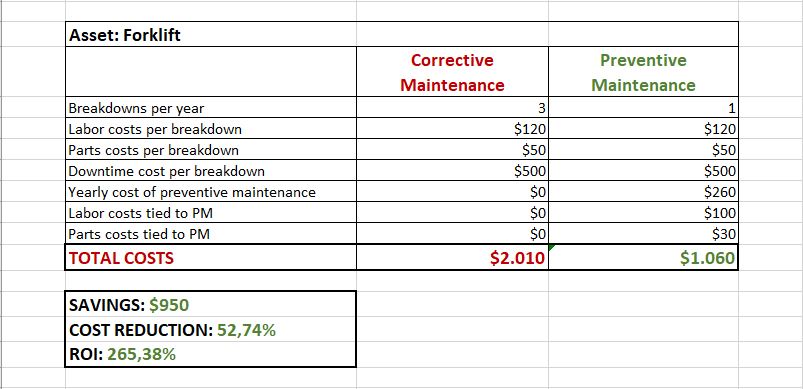

Apart from preventive maintenance (PM) and predictive maintenance (PdM), there are also corrective maintenance (CM), improvement maintenance (IM) and run to failure maintenance (RTF). For now, we will only look at the first two and their relation with the machinery and each other.

Predictive maintenance clearly marks a turning point in the world of industrial services. Unlike previous ap – proaches, such as reactive service models, preventive maintenance, and condition-based maintenance, pre – dictive maintenance adds a critical edge to the use of sensors and measuring machine data: It applies algo – rithms to predict the best point in time for carrying out maintenance

The basics of predictive / preventive maintenance White Paper Maintenance costs, as defined by normal plant accounting procedures, are normally a major por-

Corrective, Preventive, Predictive and operational maintenance must be performed by qualified and experienced I&C maintenance personnel, because of the complexity of existing control systems that utilize many fields of expertise, several maintenance

Predictive Maintenance IoT solutions together with Comarch FSM enable even more proactive issue resolution by field service staff. With sensors on machine parts, you can monitor, for example, data about temperature, weather, dust, or humidity levels, to …

preventative maintenance plan is now a predictive diagnostic tool that optimizes the efficiency of the Emax circuit breakers. The aim of LEAP is to give the customer a complete report,

Preventive maintenance (PM) is a time-based or interval-based planned service to detect and prevent potential failures and extend the life of equipment.

This edition applies to Version 2.0 of the IBM Predictive Maintenance and Quality Solution. This document was created or updated on June 25, 2015. Note: Before using this information and the product it supports, read the information in “Notices” on

the average maintenance cost for plants operating a predictive maintenance program on their pumps – comparatively the average reactive maintenance cost is 18 USd/hp p.a and the average preventative cost is 13 USd/hp p.a.

In order to see maintenance planning and scheduling we need to see it in context of the organisational systems. We need to see the role of maintenance within an organisation. www.ipamc.org Professor John Sharp, University of Salford, UK “Maintenance Planning and Scheduling” Maintenance It is: • Work necessary to maintain and preserve plant and capital equipment in a …

rely on time-based preventive maintenance to minimize downtime. While less costly than breakdown maintenance, repairing or replacing components, just because the clock or counter says to do the work, is not cost-effective. The gold standard for effective mainte-nance is a predictive approach that guides decisions about production assets. It monitors each asset’s condition to determine its

Preventive vs. Predictive Maintenance Preventive and predictive maintenance have similar objectives. Like any proactive strategy, these plans are set in place to establish a regular maintenance routine that allows a company to reach minimum or maximum standards.

Preventive, Predictive, and Corrective Maintenance.pdf – Download as PDF File (.pdf), Text File (.txt) or view presentation slides online.

Predictive maintenance differs from preventive maintenance because it relies on the actual condition of equipment, rather than average or expected life statistics, to predict when maintenance will …

2 being the most useful density function for reliability calculations, analysis of the Weibull distribution provides the information needed for troubleshooting, classifying failure types, scheduling preventive maintenance and scheduling

13/01/2016 · This mom forgot her baby in the car parked in the sun – so chocking preventive campaign

Preventive Maintenance PMP and Predictive Maintenance LEAP for New Emax Air Circuit-Breakers Brochure Low Voltage Service May 2012

complete guide to predictive and preventive maintenance Download complete guide to predictive and preventive maintenance or read online books in PDF, EPUB, Tuebl, and Mobi Format.

complete guide to predictive and preventive maintenance

data in order to deliver a fully predictive and preventive maintenance service in the near future – and soon, it will be able to do this for escalators as well. Elevators are

The preventive and predictive maintenance services offered by Central Mechanical are both comprehensive and tailored to individual client needs. Participating in Central Mechanical’s commercial HVAC maintenance plan offers business owners many benefits:

Compared with preventive maintenance, predictive maintenance: ensures that a piece of equipment requiring maintenance is only shut down right before imminent failure. This reduces the total time and cost spent maintaining equipment. – crisis assessment intervention and prevention pdf Complete Guide to Predictive and Preventive Maintenance [Joel Levitt] on . *FREE* shipping on qualifying offers. This is the CD-ROM Only version pf this book. A

The goal of predictive maintenance is to solve the challenges of both reactive and preventive maintenance without running to failure or replacing a healthy part. With predictive maintenance, planned and unplanned downtime, high maintenance costs, the potential for further asset damage, and unnecessary maintenance on working assets is decreased.

Predictive maintenance expands conventional condition monitoring approaches by looking into the “future of the machine”, thereby offering new options for increasing efficiency and for reducing the total cost of ownership (TCO). Schaeffler’s “Drive Train 4.0” technology demon-strator links existing technology with new digital services. In this way, we are taking a big step forward in

the Maintenance? Maintenance testing and repair is usually performed by a specialized electrical testing company. This type of company engages solely in the evaluation and testing of electrical equipment and systems. An independent testing firm provides high quality preventive maintenance services and unbiased test results to verify the condition of the installed electrical apparatus

Fig. 1 Preventive Maintenance Schedule [6] Each of the three parts of the analysis is utilized to address specific aspects of the maintenance.

planning paradigms are corrective, preventive and predictive maintenance. Corrective maintenance is done after a failure has occurred and it often causes downtime.

IBM Predictive Maintenance and Quality 2.0 Technical Overview

Preventive/Predictive Maintenance Systems appa.org

Electric Motor Predictive and Preventive Maintenance Guide

Vibration measurements in predictive maintenance

USING STATISTICS TO SCHEDULE MAINTENANCE

Predictive Maintenance Explained reliableplant.com

Predictive Maintenance 4.0 Predict the Unpredictable PwC

Development of a Predictive and Preventive Maintenance

aacvpr guidelines for cardiac rehabilitation and secondary prevention programs – [PDF Download] Complete Guide to Predictive and Preventive

Preventive Predictive and Corrective Maintenance.pdf

Reactive vs Preventive vs Predictive Maintenance VIZIYA

Elevator Technology MAX Predictive maintenance solution

Predictive Maintenance 4 Schaeffler Group

Preventive Predictive and Corrective Maintenance.pdf

Summary Predictive maintenance is surely one of the most talked-about topics in maintenance and asset management. In order to find out where companies currently stand regarding predictive maintenance,

Predictive Maintenance IoT solutions together with Comarch FSM enable even more proactive issue resolution by field service staff. With sensors on machine parts, you can monitor, for example, data about temperature, weather, dust, or humidity levels, to …

8/31/2015 1 Preventive/Predictive Maintenance Systems APPA INSTITUTE FOR FACILITIES MANAGEMENT This is your session Administrivia Who are you?

In order to see maintenance planning and scheduling we need to see it in context of the organisational systems. We need to see the role of maintenance within an organisation. www.ipamc.org Professor John Sharp, University of Salford, UK “Maintenance Planning and Scheduling” Maintenance It is: • Work necessary to maintain and preserve plant and capital equipment in a …

Vibration measurements in predictive maintenance by Christian Claessens, Mobil Plastics Europe Inc. Introduction In July 1980, the first production partment with its workshops, labora- last two and a half years, the alterna-

Predictive maintenance (PdM) is maintenance that directly monitors the performance and condition of equipment during normal operation to reduce the likelihood of failures. Also known as condition-based maintenance, predictive maintenance has been formally utilized in the industrial world since the

predictive maintenance delivers the most significant benefits: the production line, field level customer service and warranty claims. Preventive maintenance in action Motorcycle manufacturer By adding predictive maintenance capabilities to its warranty claims, a leading motorcycle manufacturer reduced the time to detect quality issues from days and weeks to minutes and hours, thereby

Apart from preventive maintenance (PM) and predictive maintenance (PdM), there are also corrective maintenance (CM), improvement maintenance (IM) and run to failure maintenance (RTF). For now, we will only look at the first two and their relation with the machinery and each other.

Complete Guide to Predictive and Preventive Maintenance [Joel Levitt] on . *FREE* shipping on qualifying offers. This is the CD-ROM Only version pf this book. A