Preventive and breakdown maintenance pdf

Preventive vs Predictive Maintenance . Maintenance is a very common word that everybody thinks he knows about. You carry out regular servicing of your car or motorcycle to keep it running in top condition as you know that you may face problems without their maintenance.

Preventive maintenance is intended to restore the equipment to full operational condition by replacing worn parts together with cleaning and lubricating where necessary. Corrective maintenance of pressure regulators required as a result of breakdown.

Efficiency in corrective maintenance after breakdown or after perceived deficiences that are preventive maintenance, for financial reasons. At the time of the thesis the actual !”#$$

.1 This preventive maintenance procedure is used to inspect overhead conductors and support cables. SCHEDULING This procedure shall be done once every years. LOCK-OUT 1 The Ministry policy for lock-out procedures is as per Section 6 of the Policy Section of this manual, if required. CHECKLIST TERMS Check: Inspect the equipment, then record problems for corrective maintenance at the end …

Preventive maintenance (PM) scheduling is a very challenging task in printed-circuit manufacturing due to the complexity of flexible printed circuit fabrication …

maintenance+Cost of executing preventive maintenance+Cost of executing breakdown maintenance+Lost earnings during breakdown maintenance+Lost earnings during preventive

Breakdown maintenance is maintenance performed on equipment that has broken down and is unusable. It is based on a breakdown maintenance trigger . It may be either planned or unplanned .

Hi , I am having a bit of confussion between corrective and breakdown maintenance And i also dont know what is the difference between material and equipment . So i request you to help me in order to enhance my knowledge .with regards,M.Sreeram

The simplest maintenance strategy is that of ‘breakdown maintenance’. This is where assets are deliberately run until they fail. When failure occurs, reactive maintenance is performed to fix the asset and return it to full operation. This approach is common when equipment failure doesn’t significantly affect operations or productivity.

•Introduction • Effective Maintenance Overview • Planned Maintenance • Preventative Maintenance • Predictive Maintenance • Breakdown Maintenance

Breakdown and Preventive Maintenance – Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. Scribd is …

7 Breakdown Maintenance Planning Tips With CMMS Software

Preventive Maintenance Interval Prediction a Spare Parts

Breakdown maintenance is when the organization only conducts maintenance on a piece of equipment when the equipment breaks down. Preventive, and even predictive maintenance, is when an organization conducts maintenance activities, including inspections, to help ensure equipment is functioning within their expected parameters and to catch indications of minor issues, so that they …

A successful preventive maintenance program is dependent on the cooperation of all the parties involved. Maintenance managers must rely on the knowledge, ideas, and contributions of all the maintenance personnel at the property.

With preventive maintenance, since fixing machinery is based on time and the breakdown rates of similar parts, the field service tech will replace or repair parts based on their expected failure dates. This date is not based on performance data of the specific machine.

Predictive Maintenance FS0310_C1_CVR.qxd 12/8/03 8:14 AM Page 1. G iven today’s competitive business envi- ronment and thin margins, plants sim-ply can’t afford to wait for critical equipment to fail before making repairs. Nor can they rely on time-based preventive maintenance to minimize downtime. While less costly than breakdown maintenance, repairing or replacing components, just

Keywords : Total productive maintenance, Preventive maintenance, Overall equipment efficiency, Boiler plant, Malt manufacturing industry. I. INTRODUCTION PM is a unique Japanese philosophy, which has been developed based on the productive maintenance concepts and methodologies. This concept was first introduced by M/s Nippon Denso Co. Ltd. of Japan, a supplier of M/s Toyota Motor …

4 Medical equipment maintenance programme overview Preface Health technologies are essential for a functioning health system. Medical devices in particular are crucial in the prevention, diagnosis, and treatment of illness and

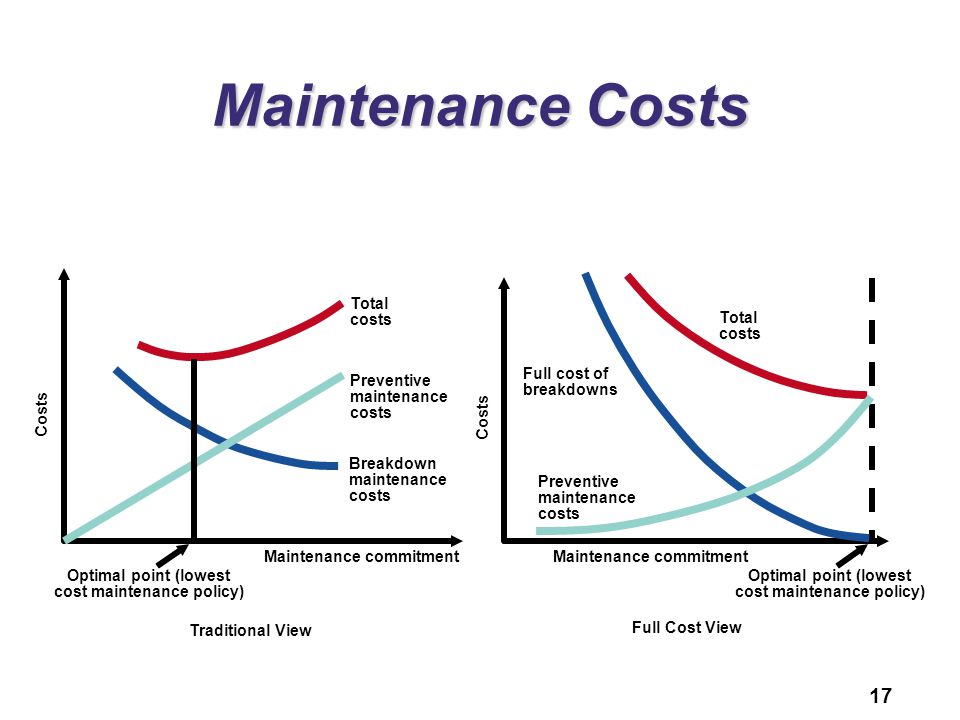

The above cost graph is a reflection of the relationship between the cost of preventive maintenance, breakdown maintenance and the loss of production over the 1 “, 2nd and 3rd generation maintenance …

Preventive and predictive maintenance 700zb00102 4-2 preventive/predictive maintenance the guiding principle of ppm is the regular and systematic application of…

Ratio of Preventive to Breakdown Maintenance Ratio of Preventive Man Hours to Breakdown Man Hours. • A measure of planning / scheduling process effectiveness and its influence on breakdown maintenance. Formula – Preventive repair man hours is maintenance that is performed as a result of a preventive inspection. – Preventive inspection man hours is work performed that originates from

Introduction: Plant maintenance is an important service function of an efficient production system. It helps in maintaining and increasing the operational efficiency of plant facilities. Maintenance is the procedure of finding the faults in any equipment/Machine and also removal of fault. It may be before the breakdown or after the breakdown.

Breakdown maintenance planning tips 1. Prioritize your preventive maintenance… Prioritize your preventive maintenance… What you can do to make your maintenance team more effective in handling equipment breakdown maintenance and other maintenance emergencies.

Preventive Maintenance (PMP) and Predictive Maintenance (LEAP) for Emax Air Circuit Breakers Brochure Low Voltage Products Service

Topic 1 MAINTANANCE Preventive and Breakdown Maintenance Comparisons – Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. Hotel Engineering for BDTHS students. SMS to 9338227504 (india) for more

Preventive Maintenance Checklist: 9 Record all test results in the component maintenance log. 10 Obtain and review manufacturer maintenance instructions. Procedures

THE MAIN FEATURES OF B2B PLANT MAINTENANCE ADD-ON Machine Specifications Provides description about the machines, spares, functions, picture …

guarantees!maintenance!improvementand!vehicle!reliability.!!Implementing!aproactive! maintenance!program!thatfocuses!on!scheduled!maintenance!willreduce!costs

preventive maintenance activities at the plant, through the application of Lean tools in the management of maintenance. The article is divided into five chapters. The next chapter presents the analysis of maintenance management at the plant, and describes the classification of maintenance work used at the plant, the procedures to a request for assistance, the maintenance support software and a

Types of Maintenance Prepared By; Rathod Abhik (13MMF0001) Types Of Maintenance Breakdown maintenance Preventive maintenance 1. Periodic maintenance ( Time based maintenance – TBM) 2. Predictive maintenance I. Condition Monitoring Corrective maintenance 7. Break Down Maintenance It means that people waits until equipment fails and repair it. Such a thing …

Please believe free to contact us with any feedback comments and tips by means of the contact us page. RELATED OF Difference Between Breakdown And Preventive Maintenance

Preventative Maintenance. Example: Scheduled maintenance. Replacing filters on an HVAC every 6 months. Preventative maintenance is work done on a repeating schedule to …

¾ Breakdown maintenance preventive maintenance in the short-term ¾ Under-trained technicians can cause more damage ¾ Social Factors ¾ Organizations are output goals, etc.) ¾ always well understood ¾ The focus on minimizing organizational performance LFM Students] – ESD.60 Lean Six Sigma Systems, LFM, MIT 9/04 –is typically cheaper than than they prevent frequently structured in ways

Difference between corrective and breakdown maintenace

• Processing– Opportunity to improve the quality of repairs in reactive or breakdown maintenance. Preventive Maintenance has two features, an activity to be performed, and a frequency at which the activity is performed. A reduction in waste in Preventive Maintenance can target either the Preventive Maintenance activity or its frequency. Preventive Maintenance Activities In many

pdf. Corrective and Preventive Maintenance. 18 Pages. Corrective and Preventive Maintenance. Uploaded by , Ca is the average cost per breakdown, and Cpm is the total cost of the preventive maintenance system. 12.7 STEPS FOR DEVELOPING PREVENTIVE MAINTENANCE PROGRAM Development of an effective preventive maintenance program requires the availability of items such …

Corrective maintenance is to repair unscheduled breakdown of an equipment while preventive maintenance is to perform scheduled maintenance of an equipment. When an equipment breaks down due to fatigue or misusage, you do corrective mantenance. When an equipment is repaired because it is scheduled to be repaired from PM1 to PM5, relacing parts before they will totally failed due to fatigue

The preventive maintenance schedule formats are totally excel-spreadsheet lookalike that helps in listing the preventive maintenance schedules and guidelines according to the scenario and time basis. – low back disorders evidence based prevention and rehabilitation pdf

KPI Familiarisation plant-maintenance.com

Difference Between Breakdown And Preventive Maintenance

Products Preventive Maintenance PMP and LEAP Breakers

What is the difference between corrective and preventive

Breakdown and Preventive Maintenance Engineering

Corrective versus Preventive Maintenance What is the

Breakdown Maintenance What is it? Fiix

Reducing The Cost of Preventive Maintenance

– BENEFITS Preventive / Breakdown Maintenance for PDF

Topic 1 MAINTANANCE Preventive and Breakdown Maintenance

Breakdown Maintenance What is it? Fiix

Breakdown maintenance planning tips 1. Prioritize your preventive maintenance… Prioritize your preventive maintenance… What you can do to make your maintenance team more effective in handling equipment breakdown maintenance and other maintenance emergencies.

Efficiency in corrective maintenance after breakdown or after perceived deficiences that are preventive maintenance, for financial reasons. At the time of the thesis the actual !”#$$

The above cost graph is a reflection of the relationship between the cost of preventive maintenance, breakdown maintenance and the loss of production over the 1 “, 2nd and 3rd generation maintenance …

preventive maintenance activities at the plant, through the application of Lean tools in the management of maintenance. The article is divided into five chapters. The next chapter presents the analysis of maintenance management at the plant, and describes the classification of maintenance work used at the plant, the procedures to a request for assistance, the maintenance support software and a