Types of preventive maintenance pdf

Preventive maintenance or preventative maintenance (PM) has the following meanings: The care and servicing by personnel for the purpose of maintaining equipment in satisfactory operating condition by providing for systematic inspection, detection, and correction of incipient failures either before they occur or before they develop into major

Safety for Hydraulic Hose & Couplings Gates also offers safety and preventive maintenance programs for industrial hose. Contact your Gates representative for more information.

Preventive Maintenance. 4 Preventive Maintenance ~ Spare pump inventory: Recommended to inventory back up pumps for critical installations. – Allows for limited downtime when failures occur – Allows for lower repair cost. Pump repairs, preventive maintenance and shipping charges are lower when “emergency” work does not need to be performed Troubleshooting Noisy Operation – …

develop periodic maintenance, planned maintenance and preventive maintenance (Kister and Hawking, 2006). A production system consists of different types of …

AIG Programs Loss Control Bulletin Equipment Maintenance Checklist Safety Equipment should only be inspected, tested and maintained by qualified trained personnel.

Build preventive maintenance scheduler Plant. Theory Maintenance types: Corrective (CM) Event driven (repairs) Preventive (PM) Time driven Equipment driven Opportunistic . Equipment failure modes How does an equipment fail? Why does it fail? Preventive maintenance… Equipment Data Equipment type Failure type Mean time between failure Time needed for CM Time needed for PM PM interval

Preventive maintenance is the maintenance performed on a routine basis or as sensed by observing, listening, feeling or smelling at or near the equipment. This type

Types of Maintenance • Preventive (PM) – greasing, oil, filters • Predictive (PdM) – Inspections • Corrective – Repairs

Preventive maintenance is maintenance performed with the intent of avoiding failures, safety violations, unnecessary production costs and losses, and to conserve original materials of fabrication.

About the Tutorial SAP PM – TutorialsPoint

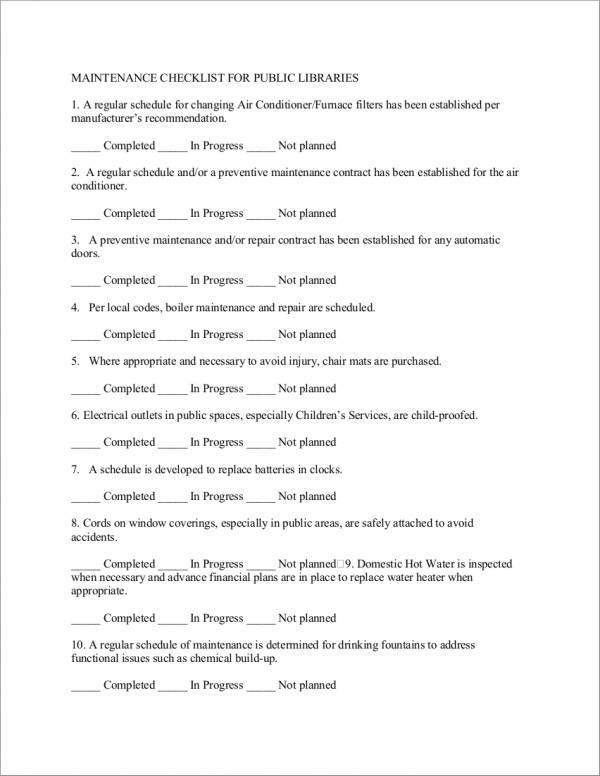

PREVENTIVE MAINTENANCE CHECKLIST State

Why Preventive Maintenance? Preventive maintenance is predetermined work performed to a schedule with the aim of preventing the wear and tear or sudden failure of equipment components. Preventive maintenance helps to: Protect assets and prolong the useful life of production equipment Improve system reliability Decrease cost of replacement Decreases system downtime Reduce injury …

Case Study Aircraft Maintenance Aircraft maintenance is the overhaul, repair, inspection or modification of an aircraft and aircraft components Airlines authorities casually refer to the detailed inspections as “checks― Different Types of checks 1. A check 2. B check 3. C check 4. D check Among all the checks A and B checks are lighter checks, while C and D are considered heavier checks.

Types of Software Maintenance. There are four types of maintenance, namely, corrective, adaptive, perfective, and preventive. Corrective maintenance is concerned with fixing errors that are observed when the software is in use.

In addition to reestablishing reliability, the second effect is operational availability. As discussed in Chapter 3, such preventive maintenance is a better option if the downtime related to corrective maintenance is higher than the downtime caused by preventive maintenance.

different types of problem and decision. b) Maintenance Strategy: combining the experiences of different tools in different circumstances to develop a robust self-help guide.

The fact of the matter is that there are three types of problems mostly encountered with centrifugal pumps: design errors poor operation poor maintenance practices The present article is being presented in three parts, covering all aspects of operation, maintenance, and troubleshooting of centrifugal pumps. The article has been written keeping in mind the level and interests of students and

t1399 7/12/07 2 appendix 1 preventive maintenance checklist emergency standby generators/switches/controls section d – air induction & exhaust system sat.

Preventive maintenance is a procedure designed to prevent failures and prolong the life of infrastructure, facilities, machines, software and other entities such as documents. The term is used to distinguish regular or precautionary maintenance from fixing things that are broken. The following are illustrative examples of preventive maintenance.

This is the fundamental difference between predictive maintenance and preventive maintenance, whereby predictive maintenance is used to define needed maintenance task based on quantified material/equipment condition.

Preventive (scheduled) maintenance (PM) This strategy is employed by most companies and almost all small to mid-sized companies make exclusive use of it. Preventative maintenance consists of assets being taken offline, inspected at periodic, predetermined intervals and repaired if necessary.

Types of power generation systems Benefits of a preventive maintenance program Power generation maintenance items Contingency Plans involving the use of Portable/

ME05 PREVENTATIVE MAINTENANCE TECHNICAL DATA SCHEDULES Air Conditioner – Split Type MECHANICAL Activity Type Of Service Last Amendment Date: 22/03/2018 A B C D E

TYPES OF MAINTENANCE Generally maintenance is classified into four categories: Preventive maintenance Corrective or Breakdown maintenance Scheduled maintenance Predictive (Condition-based) maintenance (some authors prefer three categories- scheduled and preventive maintenances are merged) TYPES OF MAINTENANCE (Cont.) There are also some other types of maintenance; i.e. Operational Maintenance

3 Preventive Maintenance Recommended to check the following: – Weekly • Record suction/discharge gauge readings • Record elapsed time meter readings

preventive maintenance to be carried out, improve and ensure maximum utilization of maintenance facilities, and improve the maintenance organization. For understanding the most used maintenance systems (fig. 1) is necessary to define some terms[2],[3]:

maintenance unit could thereby specialize in their type of maintenance. 1.4 Problem analysis SKF had a goal of decreasing the time used for corrective maintenance in relation to

Preventive railway maintenance works are performed in order to reduce the probability of the occurrence of a failure on the components of the railway infrastructure and/or maximise the operational benefit (see Kumar et al.

TECHNICAL DATA SCHEDULES PREVENTATIVE MAINTENANCE

The basic types of maintenance falling under MRO include: Preventive or scheduled maintenance, where equipment or facilities are inspected, maintained …

management, maintenance, and computerized maintenance management systems. Each of these documents can be used as a stand-alone document, but together they present all of the factors to consider when developing a medical equipment maintenance

Preventive Maintenance Checklist: Asset Type: GENERATOR. Preventive Maintenance Checklist: 9 Record all test results in the component maintenance log. 10 Obtain and review manufacturer maintenance instructions. Procedures

Transformers: Basics, Maintenance, and Diagnostics vii Contents (continued) Page 4. Oil-Filled Transformer Inspections (continued) 4.3 Winding Temperature Thermometers…..

About the Tutorial SAP Plant Maintenance (SAP PM) is a software product that manages all maintenance activities in an organization. Plant Maintenance module consists of key activities to include inspection, notifications, corrective and preventive maintenance, repairs, and other measures to maintain an ideal technical system. Audience This tutorial has been prepared for anyone who has a …

topics relating to software maintenance are types of software maintenance, software maintenance problems, software maintenance tools and techniques, and software main- tenance costing.

rely on time-based preventive maintenance to minimize downtime. While less costly than breakdown maintenance, repairing or replacing components, just because the clock or counter says to do the work, is not cost-effective. The gold standard for effective mainte- nance is a predictive approach that guides decisions about production assets. It monitors each asset’s condition to determine its

A preventive maintenance schedule consists of regular inspections and component replacements according to the product specific maintenance schedule. Maintenance schedules are based on ABB’s decade’s long experience of manufacturing and maintaining its products. Regular preventive maintenance helps facilitate forward budget planning.

3 1. INTRODUCTION This and the following instruction address the more common situations encountered in motor installation, operation and maintenance. – low back disorders evidence based prevention and rehabilitation pdf preventive maintenance given in WHO Technical Report Series No. 961, 2011, Annex 9: Model guidance for the storage and transport of time- and temperature-sensitive pharmaceutical products 3 .

Generator System Preventive Maintenance and Contingency

Types of maintenance SlideShare

OPERATION MAINTENANCE MANUAL FOR THREE PHASE

Efficiency in corrective maintenance

Preventive Maintenance an overview ScienceDirect Topics

CHAPTER VI MAINTENANCE AMRClearinghouse.org

Equipment Maintenance Checklist Individuals & Families

RISK-BASED MAINTENANCE & INSPECTION DECISIONS John

the rational male preventive medicine pdf download – Pump Maintenance Repair

Scheduling Preventive Railway Maintenance Activities

Equipment Maintenance Checklist Individuals & Families

Efficiency in corrective maintenance

Preventive railway maintenance works are performed in order to reduce the probability of the occurrence of a failure on the components of the railway infrastructure and/or maximise the operational benefit (see Kumar et al.

rely on time-based preventive maintenance to minimize downtime. While less costly than breakdown maintenance, repairing or replacing components, just because the clock or counter says to do the work, is not cost-effective. The gold standard for effective mainte- nance is a predictive approach that guides decisions about production assets. It monitors each asset’s condition to determine its

Why Preventive Maintenance? Preventive maintenance is predetermined work performed to a schedule with the aim of preventing the wear and tear or sudden failure of equipment components. Preventive maintenance helps to: Protect assets and prolong the useful life of production equipment Improve system reliability Decrease cost of replacement Decreases system downtime Reduce injury …

TYPES OF MAINTENANCE Generally maintenance is classified into four categories: Preventive maintenance Corrective or Breakdown maintenance Scheduled maintenance Predictive (Condition-based) maintenance (some authors prefer three categories- scheduled and preventive maintenances are merged) TYPES OF MAINTENANCE (Cont.) There are also some other types of maintenance; i.e. Operational Maintenance